Former manual machinists make some of the best CAM programmers. If you don’t believe it, ask Brian Prigel.

Brian, a long time manual machinist saw an opportunity to start his own business in a post 9/11 environment where a lot of good CNC equipment became available at very attractive prices. Prigel Machine (Hood River, Oregon) soon leveraged the owner’s deep manufacturing skills to attract contracts to make complex parts for such things as unmanned aviation systems (i.e. drones,) cameras and ground support equipment.

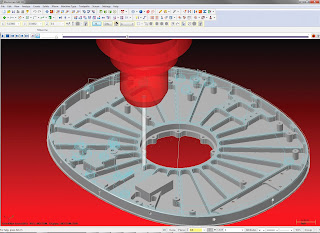

|

| A camera base from Prigel Machine. |

In 2006, to keep pace with the volume and growing complexity of the parts customers were sending, he purchased his first seat of Mastercam and has never looked back. Today, Prigel Machine has 11 CNC spindles that are programmed with four seats of Mastercam (one Multiaxis, two Mill Level 3, and one Lathe).

Prigel himself is one of the three programmers. Having limited CAD/CAM experience, he admits that he struggled with the software at first. However, a tenacious self-learner, he soon discovered where everything was in the program.

|

| Brian is one of three programmers using Mastercam in his shop. |

He said, “A lot of people that come directly out of school or don’t have the machining background do what I call ‘black box’ programming where they just take the defaults and whatever comes out is what they get. I approach it differently. Having come from manual machining to CNC, I always know what I want the tool to do. I have never encountered a situation where I couldn’t get Mastercam make the tool do exactly what I wanted it to. “

Prigel believes that manufacturing represents a very promising career path for young people today. His own success is proof. Since 2003, Prigel Machine’s sales have been progressively higher every year except one. Now the company plans to break ground for a new facility to accommodate this growth in the spring of 2012. The company is actively looking for good Mastercam programmers.