The Stewart-Haas manufacturing center supports three NASCAR teams, each with 15 cars. There are three engineering groups designing parts for these cars. One stays primarily at the track making modifications to part designs that need to be installed in time to perform in next week’s race. This does not mean that the shop will be making 45 of the same part for each of the cars because each racing team may have different ideas about the modifications that they would like to make before the next race.

Brad Harris, Shop Manager for Stewart-Haas racing said, “Our engineers are continually looking for the Magic Bullet, a design modification that will give our team a competitive advantage. These nuances are so important that we only share them with others on the team on a need to know basis.”

We don’t have to wait until race day to get feedback on how we are doing. We have a 7-post hydraulic track simulator that we can use to measure and analyze anything on the car along with a 180 mph full scale rolling road wind tunnel. These things allow us to capture and analyze test data and create a package that allows the car to go as fast as we can make it within the rules. Of course, many other teams are doing exactly the same thing.

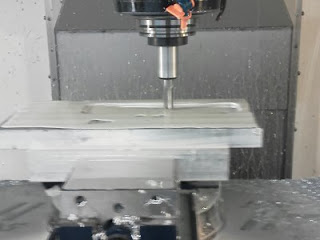

There are literally hundreds of adjustments that are made on these cars every week and most require new parts manufactured with the shop’s eight Haas 3- and 5-axis mills and their four Haas lathes. The shop team manufactures a wide range of modified parts for chassis, suspension, body, brakes, electrical, EFI, and driver controls.

Engineers leave their part designs on the server and Harris will evaluate the requirements and then assign Mastercam programming either to himself or one of the two programmers who works with him. All the part designs are kept on the server where any programmer can retrieve them and import them into Mastercam. When several versions of the same part are required that week, they are treated as a part family within Mastercam to eliminate the extra work involved in making separate CAM programs for each.

Ironically, the racing season is relatively normal time for the Stewart-Haas Racing Team. After the last race in November, things will really heat up at the shop. The shop will then be back to 10-hour days racing to manufacture new part designs for next year’s cars.