The Public Beta program for Mastercam 2026 is now available! Here’s a look at how to participate in our Public Beta program and the top new features we are most excited for you to try in Mastercam 2026 Public Beta.

How to Access Mastercam 2026 Public Beta

If you’re a Mastercam CONNECT user, you can log in to your Mastercam account and download the free Public Beta version of Mastercam 2026.

Participants in the Public Beta program will get an early look at dozens of powerful new features and enhancements before they are released to the general public. The Public Beta download includes comprehensive What’s New documentation detailing the new features across the product allowing for increased productivity, enhanced integration, and streamlined workflow efficiency.

One of the benefits of being a user on Mastercam CONNECT is the ability to have your voice help guide the development of each new release of the world’s most widely used CAD/CAM software. From our customer feedback program to Public Beta cycles, your expertise as a Mastercam user helps prioritize new developments and identify areas for improvement.

Not a Mastercam CONNECT user? Learn more or connect with your local Mastercam Partner to learn more about the benefits of Mastercam CONNECT.

Mastercam 2026 Public Beta Highlights

Here are a few highlights we are most excited to share with you in the Public Beta version of Mastercam 2026:

Mastercam 2026 introduces advanced solid hole functionality, classic mill toolpath support in Mill-Turn, and new Planes and Levels Managers. These enhancements provide better control, customization, and organization, making it easier for designers and CNC programmers to create and manage their projects efficiently.

1. Enhanced Solid Hole Functionality

Various productivity improvements have been added to Mastercam 2026 to allow users to complete tasks more swiftly and accurately, increasing productivity, saving time, and resources.

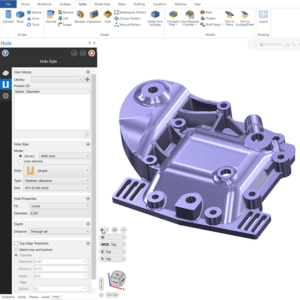

Mastercam 2026 introduces a new way to create holes in solids, organized into three panels: Geometry Selection, Hole Style, and Advanced. This allows you to design different types of holes in a solid with precision and control through new features and functions.

The Hole Style tab offers options like Style, Type, and Hole Properties, with choices from an Industry Standard library or user-defined holes, which can be saved for future use. Hole styles include Simple, Counterbore, Countersink, Taper, Threaded, and Custom, with varying options based on the style.

These enhancements provide better control and customization, with metadata on hole faces accessible from the Solid Manager. Presets can be stored in user libraries, and new Engineering standard libraries offer better size access. Designers and CNC programmers will benefit from these improvements in defining holes and creating toolpaths.

Solid Hole Void Support

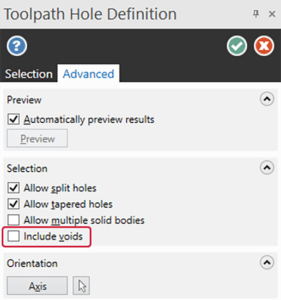

Another key new feature is Solid hole void support. This feature is found on the Hole Segments page of a Hole Making toolpath. When creating a hole for a hole-making toolpath, the new Include voids checkbox allows selection control of voids between hole segments. The resulting single-hole form includes collinear hole segments and the voids between them, forming a single hole.

When the Include Voids checkbox is unchecked, collinear holes with voids between them are considered individual hole forms.

2. Classic Mill Toolpath Support in Mill-Turn

Mastercam 2026 offers expanded system functionality as users need additional capabilities and customization allowing for an improved user experience and enhanced integration.

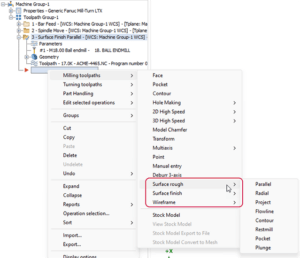

A benefit to hole-making users, Mastercam 2026 now allows Mill-Turn users to access the full suite of surface rough, surface finish, and wireframe toolpaths, totaling 28 options.

Mastercam 2026 retains its familiar toolpath interface and introduces a new Setup tab for Mill-Turn machines, moving some Toolpath parameters to align with the Mill-Turn workflow. This includes axis combination, rotary axis, and plane selection.

Access toolpaths by right-clicking in the Toolpaths Manager and selecting Milling toolpaths.

3. New Planes Manager

Various usability improvements have been added to Mastercam 2026 such as the Planes and Levels Managers allowing for users to achieve optimal workflow efficiency. With a unified workflow, users are able to transition seamlessly from design to analysis, simulation, and manufacturing.

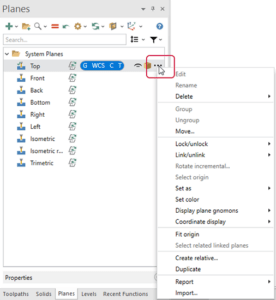

The newly designed Planes Manager has planes organized into a tree structure, allowing you perform functions such as create groups and nested groups, drag-and-drop within the tree, search the tree, and filter the tree by groups.

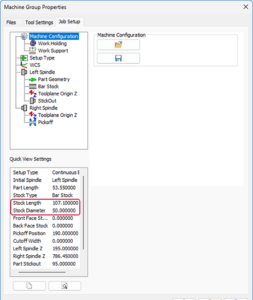

Job Setup Improvements

Several conveniences have been added to Job Setup to streamline the workflow for Mill-Turn users. In the Job Setup process, Mastercam creates a number of planes for use in programming your part. Mill-Turn users can now tell Mastercam to organize these planes into groups. As a convenience, the stock length and diameter have been added to the Quick View Settings display.

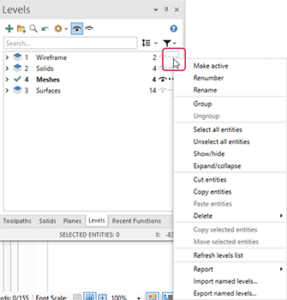

4. New Levels Manager

Mastercam 2026 features a newly designed Levels Manager, with levels organized into a tree structure. The new manager allows you to perform functions such as create and nest groups, drag-and-drop within the tree, search the tree, and expand and collapse groups for better organization. The Levels Manager’s tree structure lets you see the entities on any level.

Join Today!

From enhanced solid hole functionality and classic mill toolpath support in Mill-Turn, to the New Planes and Levels managers, Mastercam 2026 increases productivity, enhances integration, and streamlines workflow efficiency to solve the world’s manufacturing challenges. Join the Public Beta program today to experience these advancements and help shape the future of the world’s leading CAD/CAM software. Happy machining!